Measuring of the rotor geometry and the pitch angle

Contact:

Dipl.-Ing. (FH) T. Kleinselbeck

Dipl.-Ing.(FH) R. Lieckfeldt

M.Sc. S. Scheer

INITIAL SITUATION

The aerodynamic characteristics of the rotor or of the individual rotor blades largely determine the efficiency of a wind turbine. Experiences of load, noise and power curve measurements show, that even small deviations in the setpoint adjustment of rotor blades can lead to significant aerodynamical unbalances. The consequences are loss of performance, higher noise levels and increased loads at the wind turbine.

MEASUREMENT METHOD

Figure 1: Measurement at the wind turbine

Figure 1: Measurement at the wind turbine

WIND-consult developed a measurement method that allows the contact-free, laser-optical scanning of the rotor geometry respectively the rotor blade angle setpoint. 3D coordinates of the rotor will be recorded from the ground of the wind turbine with a tachymeter (see Figure 1).

The instrument works reflectorless and saves the timeconsuming and technical effort for the mounting of reflectors on the rotor blades. By using the affine coordinate transformation the coordinates of the measured values can be transformed into a coordinate system referenced to the rotor. The coordinate system in the rotor allows to measure at defined positions at the rotor blades.

The evaluation of a possible angular difference between the rotor blades is carried out on the basis of the trailing edge and a plain perpendicular to the rotor axis.

PROCEDURE OF THE BLADE PITCH ANGLE MEASUREMENT

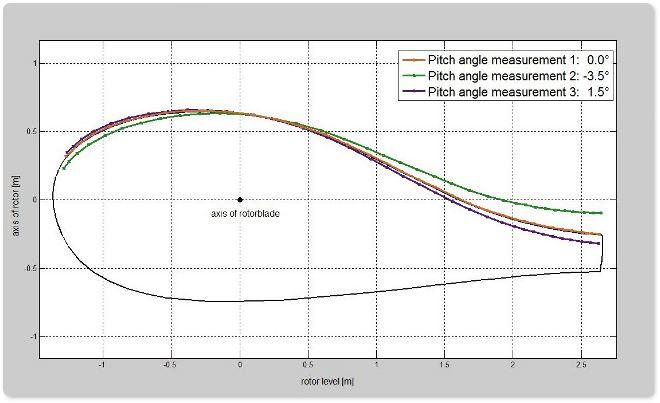

Figure 2: CAD-Model of a rotor

The measurement is performed at the stopped wind turbine. The measured rotor blade is vertically aligned in the direction of the ground and moved to the 0 ° pitch angle position (control target). In the area of the maximum chord of the rotor blade a large part of the profile section surface will be detected by discrete measurement points.

The resulting 3D coordinates get transformed and analyzed in a CAD model (see Figure 2) regarding the rotor blade pitch angle.

If the client provided a rotor blade CAD profile section, the blade pitch angle can be determined absolutely. Otherwise the angle between the rotor blades can be determined in order to identify a possible aerodynamic unbalance.

The measurement results depending on fluctuations of the wind turbine components. The survey is usually carried out at low wind speeds. The period of the measurement of the pitch angle at three rotorblades comprises about a half to a full day.

ADVANTAGES OF THE METHOD

- Precise scans of the rotor blade within centimetre range

- Measurement of the angle between the rotor blades in an accuracy range of approx. 0.2°

- Visualization of the results (see Figure 3)

- Documentation and reusability due to measured 3D data

- Possibility of comparison between measurement and CAD reference model

- Measurement at various definable positions on the rotor blade because of the reference system in the rotor

- Other measurements are possible, e.g. pre-bending and twisting of the rotor blade, high-precision measurement of the rotor diameter and hub height relating to the tower base

- No installation of equipment on the wind turbine necessary

Figure 3: Example of a measurement